Pipe Nipples

Stainless Steel Pipe Nipples

Black Steel Pipe Nipples

Galvanized Pipe Nipples

King Nipples

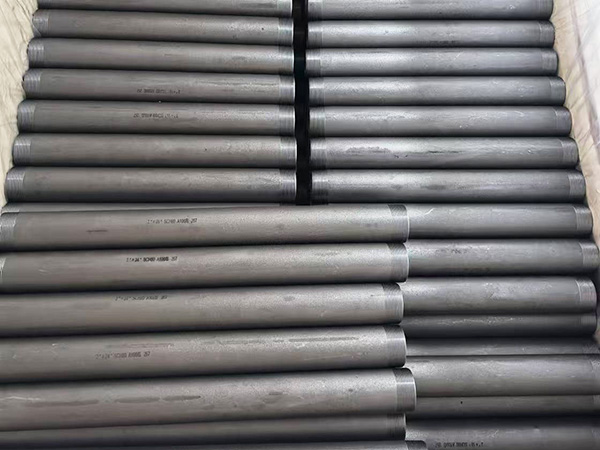

Black Seamless Nipple

There are various methods for testing the sealing performance of Black Seamless Nipples,and the following are some common methods:

Hydraulic test

Experimental principle:Using water or other suitable liquids as the medium,injecting liquid into the Black Seamless Nipple and applying a certain pressure to observe whether there is leakage in the joint,in order to test its sealing performance.

Operation steps:Connect the Black Seamless Nipple to the testing equipment to ensure good sealing.Then slowly inject liquid into the joint,exhaust the air,and gradually increase the pressure to the specified value,usually 1.25 to 1.5 times the design pressure.Maintain pressure for a period of time,usually 5 to 15 minutes,and observe whether there is any liquid leakage or dripping on the surface and connection parts of the joint.

Scope of application:Suitable for various types and sizes of Black Seamless Nipples,especially in pipeline systems with high sealing requirements,such as petrochemicals,water supply and drainage,etc.

Advantages and disadvantages:The advantage is that the detection results are intuitive and accurate,and can detect small leaks;The disadvantage is that after the experiment,the joints need to be drained and dried,and for large joints or systems,the testing cost is relatively high.

Air pressure test

Experimental principle:Compressed air,nitrogen and other gases are used as media to fill the Black Seamless Nipple and apply a certain pressure.The sealing performance of the joint is judged by observing pressure changes or detecting gas leaks.

Operation steps:Connect the connector to the gas source and pressure measuring device,and fill the connector with gas to the specified pressure,usually 1.1 to 1.15 times the design pressure.Then apply foaming agent(such as soapy water)to the surface and connection parts of the joint,and observe whether bubbles are generated;Pressure sensors can also be used to monitor pressure changes,and if the pressure drop does not exceed the allowable value within the specified time,it is considered to be well sealed.

Scope of application:Suitable for situations where hydraulic testing is not appropriate,such as systems sensitive to moisture or environments where drainage is not possible,as well as some low-pressure,large-diameter Black Seamless Nipples.

Advantages and disadvantages:The advantage is that the experimental operation is simple and fast,and there is no need for drainage treatment after the experiment;The disadvantage is that the detection sensitivity is relatively low,making it difficult to detect small leaks,and there is a certain safety risk that requires corresponding safety measures to be taken.

Helium mass spectrometry leak detection

Experimental principle:Utilizing the high permeability of helium gas and the high sensitivity detection capability of helium mass spectrometer leak detector for helium gas,helium gas is filled into the Black Seamless Nipple.If there is a leak in the joint,helium gas will escape from the leak.The helium concentration in the surrounding environment is detected by the helium mass spectrometer leak detector to determine the leak location and amount.

Operation steps:Place the Black Seamless Nipple into the sealing cover,fill the joint with helium gas at a certain pressure,and then use the probe of the helium mass spectrometer leak detector to scan and detect the joint surface and possible leakage areas.The leak detector will display a helium gas leakage signal,and determine the leakage amount and location based on the signal size.

Scope of application:Suitable for applications with extremely high sealing requirements,such as Black Seamless Nipples in aerospace,electronics,vacuum systems,and other fields.

Advantages and disadvantages:The advantage is that the detection sensitivity is extremely high,which can detect extremely small amounts of leakage and accurately locate it;The disadvantage is that the equipment is expensive,the detection cost is high,and the operation process is relatively complex,requiring professional personnel to carry out.

Halogen leak detection

Experimental principle:Using the characteristics of halogen gases(such as Freon),a gas containing halogens is filled into the Black Seamless Nipple.If there is a leak in the joint,the halogen gas leaks into the surrounding environment,and the concentration of the halogen gas is detected by a halogen leak detector to determine the sealing performance of the joint.

Operation steps:Fill the joint with gas containing halogen to the specified pressure,and use the probe of the halogen leak detector to move and detect on the surface and connection part of the joint.The leak detector will emit corresponding signals or display values based on the detected concentration of halogen gas to determine whether there is a leak and the degree of leakage.

Scope of application:Suitable for some Black Seamless Nipples that are insensitive to halogen gases and have certain requirements for sealing,commonly used in air conditioning,refrigeration and other systems.

Advantages and disadvantages:The advantage is that the detection instrument is relatively simple,easy to operate,and can quickly detect large leaks;The disadvantage is limited detection sensitivity,which may result in inaccurate detection of small leaks,and halogen gases may have a certain impact on the environment.

Ultrasonic leak detection

Experimental principle:When gas leaks from the Black Seamless Nipple,ultrasonic signals are generated.The ultrasonic leak detector is used to receive and amplify these signals,and the sealing of the joint is determined by analyzing the strength and characteristics of the signals.

Operation steps:When the Black Seamless Nipple is under working pressure or test pressure,use the probe of an ultrasonic leak detector to scan the surface of the joint and possible leakage areas.The leak detector will convert the received ultrasonic signal into audible sound or visual signal,and determine whether there is leakage based on the presence and strength of the signal.

Scope of application:Suitable for testing the sealing performance of Black Seamless Nipples under various pressures,especially for on-site rapid testing and online monitoring.

Advantages and disadvantages:The advantage is that the detection speed is fast,no special treatment is required for the joints,and the detection can be carried out without stopping the system operation;The disadvantage is that the detection sensitivity is greatly affected by environmental noise,and the detection accuracy for small leaks is relatively low.

What should I do if the stainless steel joint leaks?

Stainless steel joints are a common type of pipeline connection,which are widely used in in ...

2025-01-07

Several common problems in the use of stainless steel joints

With the continuous development of stainless steel joint technology and enterprises, stainl ...

2025-01-07

How to deal with the phenomenon of stainless steel joints shining?

A simple stainless steel joint is dipped in toothpaste or vinegar with a cotton cloth, and ...

2025-01-07

How is the hardness of stainless steel threaded fittings measured?

Stainless steel threaded fittings are generally measured by three hardness indicators:Brine ...

2025-01-07