Pipe Nipples

Stainless Steel Pipe Nipples

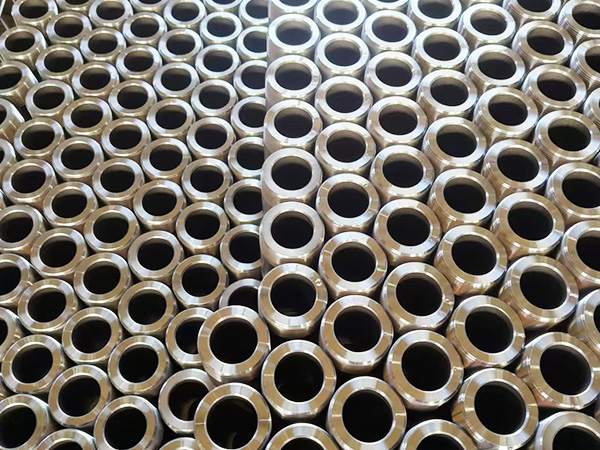

Black Steel Pipe Nipples

Galvanized Pipe Nipples

King Nipples

Black Steel Pipe Nipples

The material of Black Steel Pipe Nipples is mainly carbon steel,which can be divided into the following categories based on carbon content,alloy element content,and performance characteristics:

mild steel

Carbon content:Generally,the carbon content is below 0.25%.

Characteristics:It has good toughness,plasticity,and welding performance,with relatively low strength and hardness.Its texture is relatively soft,easy to process and shape,and can be made into joints of different shapes and sizes through various processing methods.

Application scenario:It is commonly used in situations where strength requirements are not high but toughness and welding performance are high,such as joints in general water supply and drainage pipelines,gas transmission pipelines,etc.,and galvanized steel pipe joints commonly found in building water supply and drainage systems,many of which are made of low-carbon steel.

Medium carbon steel

Carbon content:The carbon content is generally between 0.25%and 0.6%.

Characteristics:It has good comprehensive performance,with certain strength and hardness,as well as certain toughness and plasticity.By using appropriate heat treatment processes such as quenching and tempering,its performance can be further improved to meet different engineering requirements.

Application scenario:Suitable for joints in mechanical parts and engineering structures with certain requirements for strength and hardness,such as transmission shaft joints in mechanical manufacturing,some connection joints in automotive engines,etc.It can withstand certain loads while ensuring good working performance.

High carbon steel

Carbon content:The carbon content is usually above 0.6%,with a maximum of around 1.3%.

Characteristics:It has high strength,hardness,and wear resistance,but relatively poor toughness and plasticity.Due to its high carbon content,it is easy to obtain high hardness and strength during heat treatment,but it also increases the difficulty of processing and results in relatively poor welding performance.

Application scenario:Mainly used for manufacturing parts joints that require high hardness and high wear resistance,such as wear-resistant parts joints in mining machinery,some connecting components in molds,etc.It can maintain good performance and stability under high wear and high pressure working conditions.

In addition,in some special requirements,low-alloy high-strength steel containing a small amount of alloying elements will be used to manufacture Black Seamless Nipples,such as adding manganese,silicon,vanadium,titanium and other elements to further improve the strength,toughness,corrosion resistance and other properties of the joints.It is commonly used for pipeline connections and mechanical connections in harsh environments such as high pressure,high temperature,and high corrosion.

What should I do if the stainless steel joint leaks?

Stainless steel joints are a common type of pipeline connection,which are widely used in in ...

2025-01-07

Several common problems in the use of stainless steel joints

With the continuous development of stainless steel joint technology and enterprises, stainl ...

2025-01-07

How to deal with the phenomenon of stainless steel joints shining?

A simple stainless steel joint is dipped in toothpaste or vinegar with a cotton cloth, and ...

2025-01-07

How is the hardness of stainless steel threaded fittings measured?

Stainless steel threaded fittings are generally measured by three hardness indicators:Brine ...

2025-01-07