Pipe Nipples

Stainless Steel Pipe Nipples

Black Steel Pipe Nipples

Galvanized Pipe Nipples

King Nipples

Seamless Threaded Pipe Fittings

Seamless threaded pipe fittings are a type of pipe fitting product used for connecting pipelines.It is processed from seamless pipes,with threaded surfaces on the fittings.Different pipes,equipment,or other fittings are connected together through threaded connections to achieve functions such as extension,turning,branching,etc.of the pipeline system.

characteristic

Good sealing performance:Threaded connections can provide reliable sealing performance,effectively preventing fluid leakage in pipelines,especially in some low-pressure,small-diameter pipeline systems.

High strength:Due to the use of seamless pipe manufacturing,the pipe fittings themselves do not have welds,avoiding the problem of weak strength that may be caused by welds.It has high overall strength and pressure resistance,and can withstand large pressure and impact forces.

Good corrosion resistance:According to different usage environments and requirements,seamless pipes of different materials can be selected to manufacture fittings,such as carbon steel,stainless steel,etc.These materials themselves have certain corrosion resistance and can adapt to various media and working conditions.

Easy installation:The threaded connection method is relatively simple and does not require complex welding equipment or professional welding technicians.The installation process is fast and convenient,making it easy for on-site construction and maintenance.

High dimensional accuracy:The production process of seamless pipes is relatively mature,which can ensure the dimensional accuracy and surface quality of pipe fittings,making the connection between pipe fittings more tight and the fit more precise.

Common types

Elbows:Used to change the direction of pipelines,common angles include 45°,90°,and 180°,which can connect and arrange pipelines in different directions.

Tees:There are three interfaces used for branching connections of pipelines,which can distribute fluid from one pipeline to two or more pipelines,or collect fluid from multiple pipelines into one pipeline.

Crosses:With four interfaces,it is mainly used for cross shaped branch connections of pipelines and is used in some complex pipeline systems.

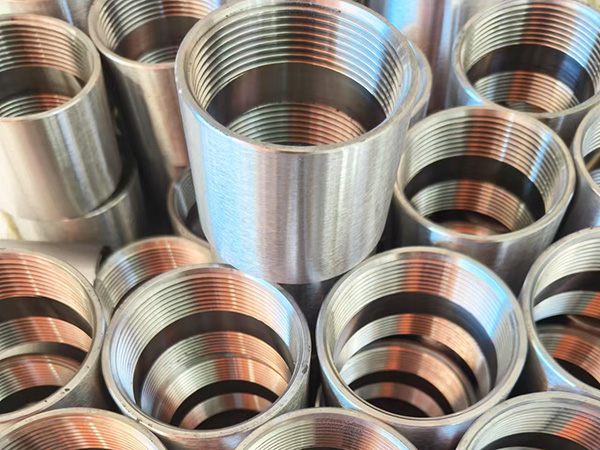

Couplings:Used to connect two pipes of the same diameter,allowing the pipes to be extended.

Reducers:Used to connect two pipes of different diameters,achieving a transition and change in diameter.

Cap:Installed at the end of the pipeline,it serves to seal the pipeline and prevent fluid leakage or external impurities from entering.

manufacturing process

Raw material selection:Select suitable seamless pipes as raw materials based on the requirements and working conditions of the pipe fittings,such as carbon steel seamless pipes,stainless steel seamless pipes,etc.Strictly inspect raw materials to ensure their quality meets relevant standards and requirements.

Cutting and cutting:Use sawing machines,cutting machines,and other equipment to cut seamless pipes into the required length of pipe sections.During the cutting process,ensure the flatness of the cut and the accuracy of the size.

Thread processing:The end of the pipe section is threaded using equipment such as thread lathes and threading machines.According to different standards and requirements,corresponding specifications of threads are processed,such as imperial threads,metric threads,etc.

Forming processing:For pipe fittings such as elbows and tees that require forming processing,hot bending,cold bending,extrusion and other processes are used to process the pipe segments into the desired shape.During the molding process,it is necessary to control parameters such as processing temperature,pressure,and deformation to ensure that the shape and size of the pipe fittings meet the design requirements.

Heat treatment(optional):In order to improve the mechanical properties,strength,toughness,and corrosion resistance of the pipe fittings,heat treatment can be carried out as needed,such as annealing,normalizing,quenching,tempering,etc.

Surface treatment:Surface treatment of pipe fittings,such as rust removal,painting,galvanizing,etc.,to improve their corrosion resistance and appearance quality.

Quality inspection:Conduct a comprehensive quality inspection of the processed pipe fittings,including visual inspection,dimensional measurement,thread inspection,pressure testing,etc.,to ensure that the quality of the pipe fittings meets relevant standards and customer requirements.

Application scenarios

Petrochemical industry:Seamless threaded fittings are widely used in various pipeline systems for transporting media such as oil,natural gas,and chemical raw materials in processes such as oil extraction,refining,and chemical production.

In the construction industry,seamless threaded fittings are used to connect various pipes and equipment such as water pipes,air pipes,heating pipes,etc.in the plumbing,heating,ventilation,and other piping systems of buildings.

Mechanical manufacturing industry:Seamless threaded fittings can ensure the sealing and reliability of hydraulic systems,pneumatic systems,lubrication systems,and other pipeline connections in mechanical equipment,ensuring the normal operation of the equipment.

In the power industry,seamless threaded fittings are used to connect various pipelines and valves in systems such as steam and water pipelines,circulating water pipelines,and chemical water treatment pipelines in power plants,ensuring the safety and stability of power production.

Food and pharmaceutical industries:In the process of food processing and pharmaceutical production,high hygiene and cleanliness requirements are placed on pipelines.Seamless threaded fittings made of stainless steel are widely used in pipeline systems in these industries due to their excellent corrosion resistance and hygiene performance.

What should I do if the stainless steel joint leaks?

Stainless steel joints are a common type of pipeline connection,which are widely used in in ...

2025-01-07

Several common problems in the use of stainless steel joints

With the continuous development of stainless steel joint technology and enterprises, stainl ...

2025-01-07

How to deal with the phenomenon of stainless steel joints shining?

A simple stainless steel joint is dipped in toothpaste or vinegar with a cotton cloth, and ...

2025-01-07

How is the hardness of stainless steel threaded fittings measured?

Stainless steel threaded fittings are generally measured by three hardness indicators:Brine ...

2025-01-07